Paper Slitter

Paper slitter is a paper trimming equipment that slits and rewinds wide web into the rolls of various widths and diameters. As a paper slitting machine, it is widely used in the paper making or printing industry.

Main structure and working principle

Paper slitter is composed of a frame, a transmission system, a feeding and discharging machine, a tension control device, a traction member, a slitting bracket, a waste winding and a discharge device. It is to divide large paper web into several independent rolls. The working principle is to fix the web on the end of the discharge shaft equipped with a magnetic powder tension control to keep constant tension required by the web, and then towed by a pair of rubber rolls. The web will be cut into several pieces by a blade. Then, the guide rolls are guided to the A and B winding rolls to wind up into the finished product. Its transmission system is driven by main motor to drive the rubber rolls and the receiving shaft to run synchronously to achieve the purpose of paper traction and the finished product receiving.

- Bracket and transmission system: Bracket consists of left and right walls and supporting and discharging machinery. The transmission system is mainly used for pulling materials and winding the finished product. It is powered by the variable frequency stepless speed regulating motor. The belt makes the traction rubber roll get running. Main traction rubber roll and the driven traction rubber roll are attached closely and run synchronously to pull the materials to move, and the active traction roll drives lower circular cutter shaft to operate to achieve better cutting requirements synchronously, and passes through lower circle. The circular cutter shaft drives the A winding and the B winding to perform synchronous operation, thereby achieving the purpose of receiving the material.

- Receiving mechanism and tension device: The receiving mechanism mainly consists of a chain, a synchronous wheel, a magnetic powder clutch and an air-expansion shaft. Two rolls are controlled by a single motor. As long as the current of the magnetic clutch is adjusted, the tension of the receiving shaft can be changed.

- Traction members: The traction members mainly consist of a pair of traction rubber rolls and a number of hard oxidized aluminum rolls, which are used to take the materials for the winding of the finished product. The power is derived from the motor passing through the V-belt to the active rubber rolls to make it run.

- Slitting holder: it has a circular slitting blade, a straight slitting blade, and a moving handle.

- Waste rewinding and discharging: The waste is discharged through the wind pipe using the blower.

- Discharging mechanism and automatic rectification: The discharging mechanism mainly consists of a discharge shaft, a support block, a cylinder, a base, left and right moving seats, etc. The automatic rectification device mainly consists of a photoelectric opening, rectification guide rolls, left and right brackets, a rectification moving plate, synchronous motor and left and right limit switches.

Performance and features

- Paper slitter adopts PLC and touch screen control, magnetic powder clutch type tension control and center winding method.

- The host is using frequency control, automatic metering, alarm shutdown, tension digital display on the touch screen.

- Discharging adopts photoelectric automatic rectification (or ultrasonic rectification) to correct the neatness of the paper, so that irregular materials can be cut normally.

- Circular blade (or straight blade) slitting, automatic waste discharging device.

- Manual (or pneumatic) charging. The discharging roll is equipped with a sleeve-type inflatable shaft (3〞or 6〞).

In order to make the machine work normally and slit high-quality finished products. And the condition of each part of the machine shall be checked from time to time and oiled with lubrication at each point.

Working environment

The working environment is used directly affects the performance and service life of the electrical appliances and components. The working environment of paper slitter should:

- Be installed in the room with good ventilation;

- Work at ambient temperature of -10°C + 40°C;

- Try to avoid high temperature and humidity of less than 90% RH with no rain dripping;

- Avoid direct sunlight;

- Stay without flammable, corrosive gases and liquors;

- Be installed with fixed base without vibration;

- Have no electromagnetic interference, and be away from interference sources.

Main products

Computer high-precision paper slitter

It is widely used in cardboard, coated paper, kraft paper, culture paper, double-adhesive paper, high-gloss photo paper, gold and silver cardboard, aluminum foil paper, laser paper, tobacco and alcohol packaging paper, etc. It is a paper slitting machine commonly used in the paper making industry and printing industry.

| Model | CHM-1400 | CHM-1700 | CHM-1900 |

| Slitting Type | Top blade rotary, bottom blade fixed | ||

| Use Scope | 60-550 GSM | 60-550 GSM | 60-550 GSM |

| Slitting Accuracy | ±0.5 mm | ±0.5 mm | ±0.5 mm |

| Max. Slitting Speed | 300 sheets/min | 300 sheets/min | 300 sheets/min |

| Max. Slitting Meter Speed | 300 m/min | 300 m/min | 300 m/min |

| Slitting Length Range | 450-1650 mm | 450-1650 mm | 450-1650 mm |

| Max. Diameter of Roll | 1800 mm | 1800 mm | 1800 mm |

| Paper-piling Height | 1300 mm | 1300 mm | 1300 mm |

| Max. Paper Slitting Width | 1400 mm | 1700 mm | 1900 mm |

| Total Weight | 12000 kg | 13000 kg | 14000 kg |

| Dimension(L×W×H) | 12158mm*3783mm*2230mm | 12158mm*4083mm*2230mm | 12158mm*4283mm*2230mm |

High-precision twin-rotary paper slitter

High-precision twin-rotary paper slitter is characterized of clean and tidy cutting and high cutting precision. It is widely applicable to cardboard, coated paper, kraft paper, culture paper, double Adhesive paper, high gloss photo paper, gold and silver cardboard, aluminum foil paper, laser paper, tobacco and alcohol packaging paper, etc.

Model | CHM-SGT1400 | CHM-SGT1700 | |

Slitting Type | Upper and lower rotary slitting mechanism | ||

Use Scope | 200-1000 GSM | 200-1000 GSM | |

Slitting Accuracy | ±0.5 mm | ±0.5 mm | |

Max. Slitting Speed | 300 sheets/min | 300 sheets/min | |

Max. Slitting Meter Speed | 300 m/min | 300 m/min | |

Slitting Length Range | 450-1650 mm | 450-1650 mm | |

Max. Diameter of Roll | 1800 mm | 1800 mm | |

Paper-piling Height | 1300 mm | 1300 mm | |

Max. Paper Slitting Width | 1400 mm | 1700 mm | |

Total Weight | 13000 kg | 15000 kg | |

Dimension(L×W×H) | 14453mm*4675mm*2350mm | 14453mm*4975mm*2350mm | |

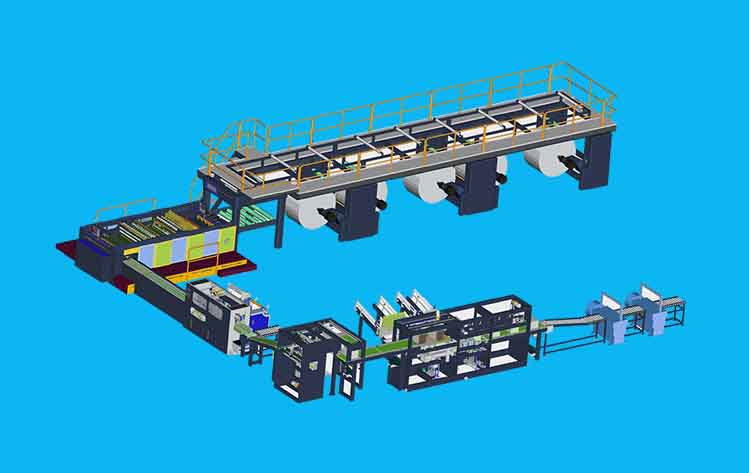

Twin-rotary A4 copy paper slitter

Twin-rotary A4 copy paper slitter is a new slitting technology for twin rotary synchronous slitting. It is a combination of paper slitting, packaging and automatic packaging.

Model | CHM-A4-4 | CHM-A4-5 |

Paper Width | 845-850 mm | 1055-1060 mm |

Production Speed | Max. 280 m/min | Max. 280 m/min |

Slitting Accuracy | ±0.2 mm | ±0.2 mm |

Paper Roll Number | 4 Rolls | 5 Rolls |

Slitting Number | 4 | 5 |

Output | Max. 37 Reams/min | Max. 47 Reams/min |

Power | 32kw+18kw+19kw | 34kw+18kw+19kw |

Dimension(L×W×H) | 17681mm*4140mm*3190mm | 20114mm*4355mm*3190mm |

As a leading paper making equipment manufacturer, AGICO can provide you with high quality paper slitting equipments and relevant information about paper slitter in details.